Challenge

A leading manufacturer of wood products in Turkey was looking to add a new chiller system for its large production facility in the region of Bursa. Surrounded by forests, the region is an important center for the Turkish furniture industry where wood processing has played a big role in the economy since the 16th century. Trane’s customer, founded more than 30 years ago, is now one of the biggest manufacturers in Turkey. It has the highest production capacity under a single roof in the whole country with 4,000 m³ chipboard and 2.000 m³ MDF every day.

For its new chiller, the customer was seeking a durable solution coupled with excellent service. The company is a pioneer when it comes to environmental concerns and energy efficiency has been a major priority for many years.

Solution

Trane worked closely with the customer to devise an energy efficient solution that would meet their technical requirements and offer exceptional reliability, within budget.

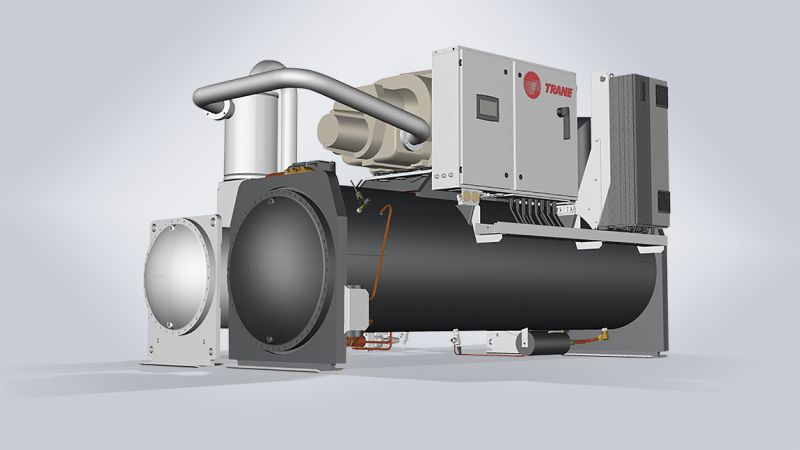

Trane supplied a large RTHD water-cooled helical-rotary compressor chiller featuring superior performances with low refrigerant charge. Delivering superior full- and part-load performance, the installed High Seasonal Efficiency version ensures even further increased savings with:

• AFD (Adaptive Frequency Drive) as standard

• Fewer start-stop cycles

• Increased compressor life

• Reduced start-up current draw

Automatic tube cleaning was also installed to continuously clean the condenser tubes. The elimination of pollution results in extended condenser lifecyle, increased overall system efficiency ; while reducing downtime and maintenance costs.

The industrial-grade design of the RTHD chiller makes it ideal for manufacturing applications and offers both High Seasonal Efficiency and robust reliability. It's the ideal choice for tight temperature control in almost any temperature and under widely varying loads.

Results

With its extensive compressor development and manufacturing experience, Trane designs and builds chillers that have higher efficiency and reliability than other units on the market. The reduced energy consumption both benefits the environment and reduces costs for the customer, making it a more economical option.

Thanks to their efficient chiller selection, Trane’s solution helps the manufacturer achieve 25% energy savings compared to their existing system.