Challenge

A German company specialising in recycling plastics for use as industrial components wanted to substantially cut energy consumption during the manufacturing process. The award-winning company, which is known for its innovation and resource efficiency, is entirely focused on turning recycled raw materials into recyclates and granulates that can be used in the creation of new products and high-quality applications.

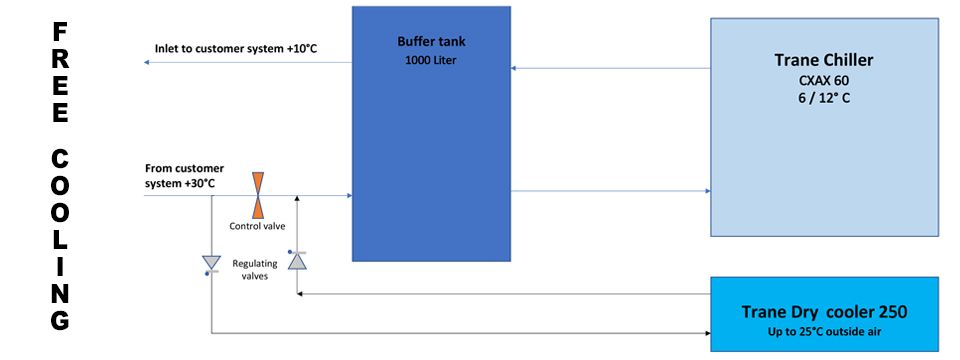

However, working with plastic extruders necessarily involves very high temperatures, with water as high as 30°C needing to be cooled to some 10°C before being reintroduced to the system. The company was already using chillers on site but was looking for ways to cut energy consumption even further while still achieving capacity of 170kW.

Solution

The local Trane Rental Services team recommended combining its high-performance, air-cooled Conquest CXAX 060 chiller with a 250kW dry cooler that would offer “free cooling” during winter months. Both units were sited outside saving on space with the chiller delivering 6°C-12°C, or 8°C-15°C. During winter months, when ambient temperatures are around 10°C-12°C, the dry cooler can take air from outside to provide totally free cooling.

Results

The customer was delighted with Trane’s solution. As the company’s main goal was to reduce energy consumption, they were extremely pleased to be achieving savings of around 30% on electricity use. In temperate climes when outside ambient temperatures are low, free cooling can be achieved for at least six months of the year and not only reduces energy consumption but can also extend chiller lifetime by reducing the load on mechanical parts.

During the hotter seasons, when no free cooling is possible, natural heating of the water is avoided by directing the flow to bypass the dry cooler. The customer was initially planning to rent the Trane units for just 12 weeks however this was extended to five years once they learned of the stand-out benefits offered by Trane’s EaaSy rental scheme.

EaaSy stands for “Equipment-as-a-Service” and it’s a formula that provides a host of advantages for customers including ongoing maintenance and 24/7 service support.

Learn more about Free Cooling