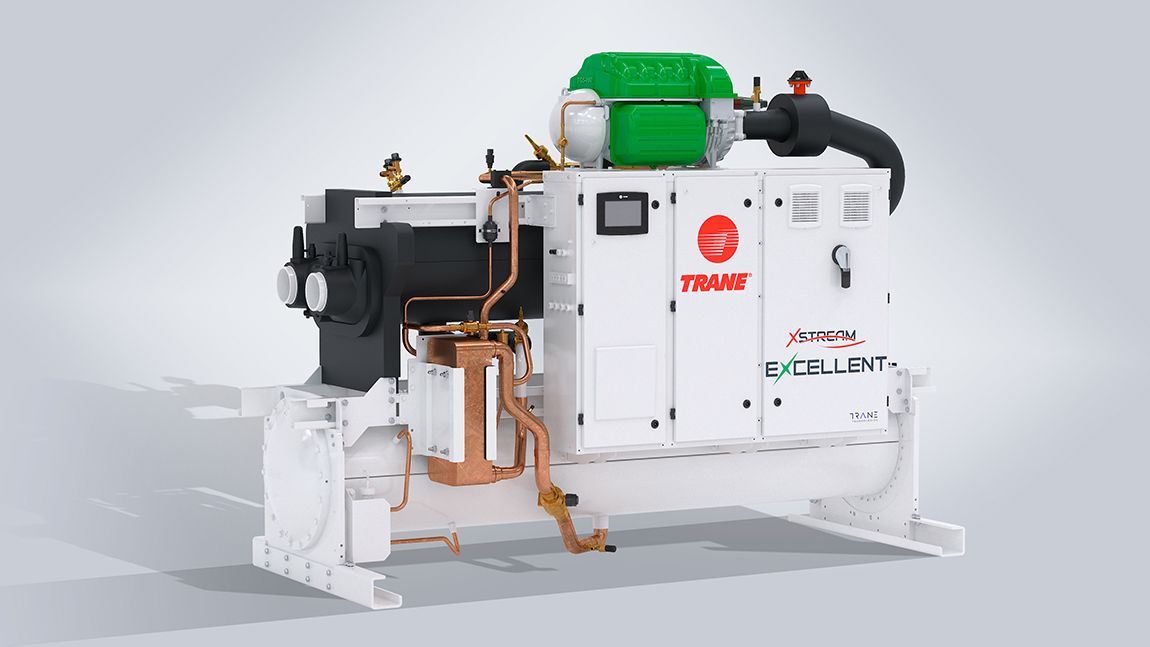

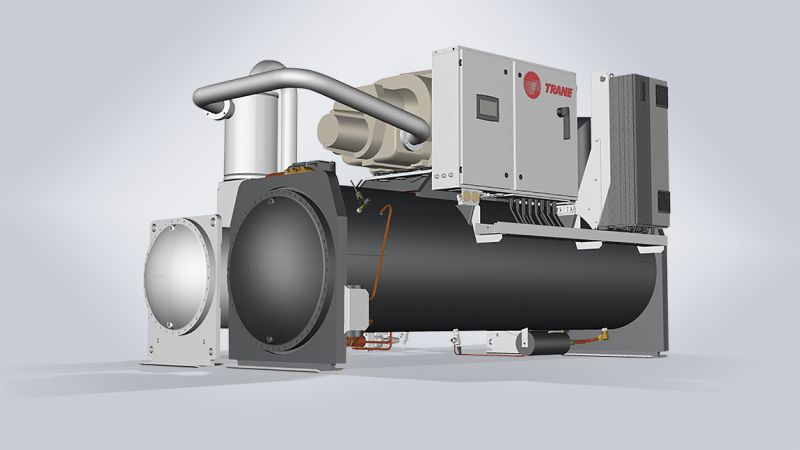

XStream™ RTWF XSE Water-Cooled Chiller

Cooling capacity: 410 - 1320 kW

- Variable Vi compressor with permanent magnet motor

- Market-leading full and part load efficiencies

- Minimized refrigerant charge with CHIL falling film evaporator

- Extended and unmatched capacities

- Trane Adaptive Control™: Tracer® Symbio™ 800 microprocessor system enhances chiller with the latest chiller control technology

Outstanding energy efficiency

The latest Trane screw compressor with Variable Volume elevates part load efficiency one step ahead by using Variable Volume Index (Variable Vi):

• Allows the chiller to operate at the most appropriate pressure ratio to reach remarkable efficiency levels.

• Increases part load efficiency (SEER) by 10% vs. the equivalent model at Fixed Vi.

• RTWF XSE can reach SEER’s as high as 9.0

Proven Trane reliability

Trane XStream™ series chillers are capable of sustaining precise temperatures at extremely tight tolerances that are key to occupant comfort and crucial to many demanding mission-critical processes through:

• Design simplicity

• Unmatched direct drive compressor, low speed, semi-hermetic compressor with only three moving parts

• Infinite unloading for exact load matching

• Tracer® Symbio™ 800 controller with patented algorithms anticipate and correct situations to keep the chiller online

• Extensive factory testing available to verify operation at customer-defined conditions

Multiple chiller plant design

The overall RTWF unit efficiency can be enhanced by using the Series counterflow design, an alternative chiller layout to the conventional parallel piped configuration.

This layout provides the opportunity for:

• Lower chilled water design temperature with larger ΔT

• Reduced design flow

• Installation and operational cost savings by using fewer installed pumps and valves, reduced pipe diameters and chiller downsizing

• Maximized system efficiency

• Continuous temperatures allow better stability of controls.

Combining series configuration with Variable Primary Flow (VPF) makes it possible to increase system efficiency even further.

Variable Primary Flow (VPF) capabilities

VPF systems provide building owners with multiple cost savings derived directly from pump operation. The XStream series is designed to make VPF easy to use:

• The evaporator on the RTWF XStream series can run safely with up to 50% water flow reduction.

• The microprocessor and capacity control algorithms are designed to handle a maximum of 10% change in water flow rate per minute in order to maintain ±0.3°C temperature control leaving the evaporator.

• For applications in which system energy savings are the priority and tight temperature control is classified as +/- 1.1°C, up to 30% change in flow per minute is possible.

• With the help of a Trane analysis tool, you can determine whether the anticipated energy savings justify the use of VPF in a particular application.

Operating Conditions: Comfort cooling ‒ From +4.4 to 20°C on the evaporator side and up to 68°C on the condenser side

RTWF XSE packaged chillers are available in five different models.

Technical Specifications

| Product name | Cooling capacity | Heating capacity | Eurovent certification | ErP Certification |

|---|---|---|---|---|

| XStream™ RTWF XSE Water-Cooled Chiller | 410-1320 kW | N/A |

| Compressor | Refrigerants | Energy saving | Operating mode | Data protocols | Unit type |

|---|---|---|---|---|---|

| Screw | R134a | Adaptive Frequency™ Drive | Cooling only Heat pump | Lonmark Bacnet Modbus Water-to-water | |

Other Products You Might be Interested In

Rental Services

Our approach to temporary HVAC and power goes beyond the typical drop-off. We design, deliver, install and even monitor safe and efficient rental solutions. Short term, long term, chiller, generator, or portable AC unit, we have the fleet and people where and when you need them.

Contact Us

Connect with your local Trane expert

We will help you find the needed solution