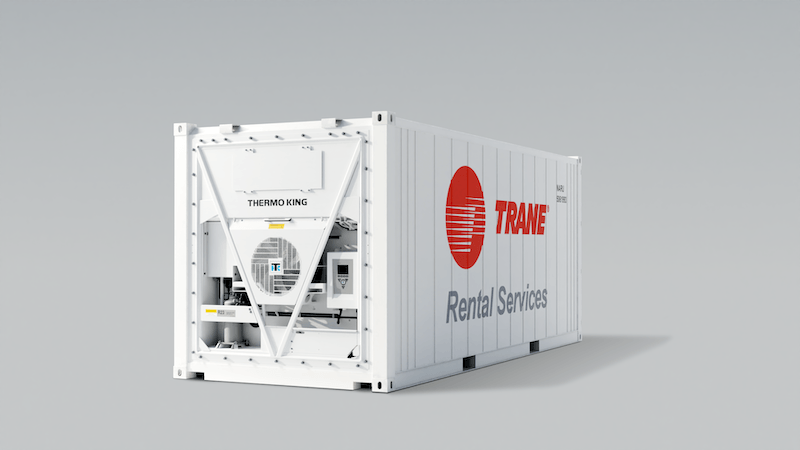

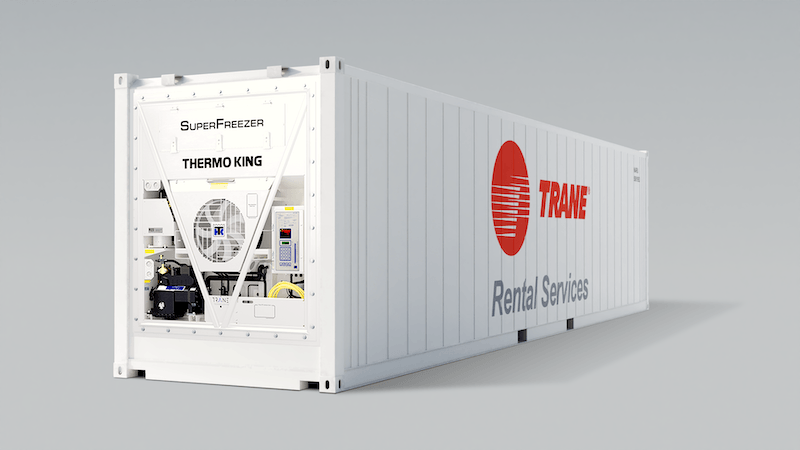

C-STORE G PLUS 20

Minimum setpoint: -30°C

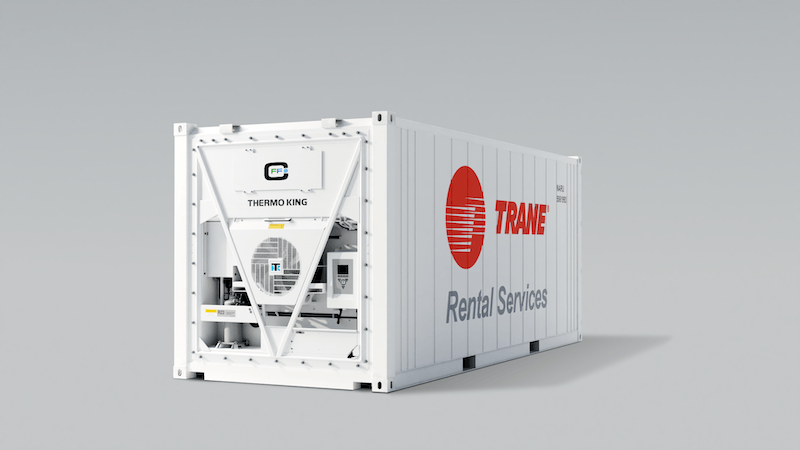

- The lowest energy consumption and most sustainable solution, with double thickness insulation and low GWP refrigerant on high efficiency Thermo King CFF unit

- Advanced temperature management control system for extremely precise temperature control over the whole operating range (-30°C to +45°C): +/- 0.25°C in chilled mode and +/- 1°C in frozen mode.

- Fast pull-down: Superior cooling capacity allows to reach specific set-points faster and increase the storage life of your shipments

- Available in size 20 ft

The lowest energy consumption

Trane C-STORE G PLUS requires the lowest energy consumption to maintain accuate temperature setpoint for chilled, fresh and frozen cargos. This is achieved by using a special container with double insulation thickness and a butcher type door to reduce air leaks and thermal bridges. The picture is completed by using the Thermo King CFF, which sets new references in terms of energy efficiency.

Precise temperature control

Trane C-STORE G PLUS is equipped with the intelligent MP-4000 controller. The controller constantly monitors the unit health and analyses current performance compared to expected values.

Smart Pre-Trip Inspection is an additional feature that runs trend analysis of the unit health over time, even when the cold store container is loaded with products.

With this feature enabled, you do not need to empty the container and make complete PTI, which saves you time and money.

A smiley face will display with a tick sign to indicate that everything is in order. The data logger saves the values and you can download results on your convenience.

Advanced fresh air management

AFAM+ protects fresh produce from detrimental atmospheric conditions or until market price is attractive. Just indicate your desired CO2 level and the fresh air exchange rate using our AFAM guide, and set these in the MP-4000 controller. AFAM+ will ensure the specified fresh air rates are maintained. Air vent logging (AVL) will also document the actual air exchange in the data logger.

If you want to charge the container with a gas to "put fresh products asleep" for a while, enter the corresponding settings in MP4000 with AFAM+, and simply delay first fresh air exchange.

Seamless connectivity

MP-4000 controller is compatible with a wide range of telematics solutions for both one-way and two-way communication. This is the ideal solution to monitor reefer units from remote, to change set-points or retrieve a datalog file. Serial connection to other systems or data transfer via API are also available.

Technical Specifications

| ISO 6346 type | R22B/12RB |

|---|---|

| Operational environment | The container is designed and manufactured for the carriage of deep frozen products at ambient temperature from +50°C to -30°C without effect on the strength of the structure. A CFF refrigeration unit of a “one piece picture frame type” fitted to the front end frame. The container is designed with a refrigeration unit to maintain the inside space temperature at +45°C to -30°C |

| Standard and regulations | The containers comply with following authorized standards and regulations: ABS, Bureau Veritas, Lloyds Register, ISO/TC-104, ISO1496-2, ISO-668, TIR, CSC. They are built to be capable of being handled without permanent deformation on following basis: Lifting, loaded or empty, at top corner fittings vertically by means of spreaders fitted with hooks, shackles or twist-locks. Lifting, loaded or empty, at bottom corner fittings using slings with terminal fittings at any angle between vertical and 45° to the horizontal. |

| Air (Q) and Heat (U) Leakages | Double thickness insulatioon, the air leakage is approximately 5 m3/hr when the inside pressure of the container is 250 Pa. The total heat loss of the container is approximately 20 W/K at mean insulation wall temperature of 20°C. |

| Insulation material | Cyclo Pentane blown rigid polyurethane foam; Flammability SE class (Self-extinguishing). In foamed sandwich panels where acrylic adhesive is coated on the inner surface of aluminum panels and stainless steel inner linings. Gasket material used on container is Ultra Polyethylene (UPE) rubber, that operates in environment down to -80°C. |

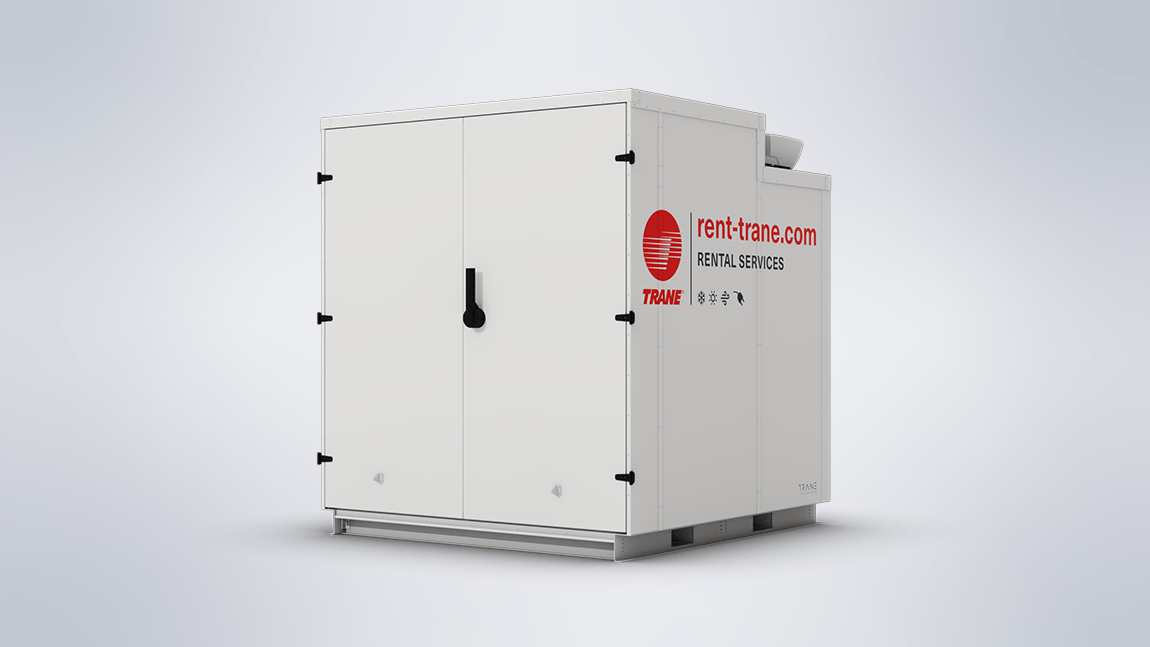

| Door access | Locking rods type w/quick entry. Width 1,100 mm (43.3") * 2,000 mm (78.7") |

| Escape door | Escape door built into door. Possible to open from inside if man-trapped. |

| Floor | The floor is composed of corrugated sub-floor and floor flat with reversed T-shaped floor-board with insulation of polyurethane. The corrugated sub-floor is welded to the lower bottom side rails. Four (4) drain holes are provided at the front and rear end of the container. The float valve in the drain cover adjusts water in and out automatically. Floor Flat Reversed T-shaped extruded aluminum, flat surface is 30 mm high. |

| Configuration | Internal light. Power on/off outside container. Unit off button with timer relay (8 min from stop to start). Curtain. Man-trap alarm button. Audio using buzzer + Visual with red flashing lamp. |

| Optional | Door ramp 1,100 mm (43.3") wide |

| Refrigerant | R134a/R513A refrigerant |

|---|---|

| Minimum setpoint | -30°C |

| Maximum setpoint | +45°C |

| Power supply | 32A 3-phase 400V 50Hz |

| Controller | mp4000 |

| Fresh air vent | Yes |

Resources

| Product e-brochure PDF document | Download |

|---|

Contact Us

Connect with your local Trane Rental expert

We will help you find the needed solution