Challenge

A large hospital on the outskirts of Paris was seeking to replace its existing chiller units. The client wanted to install a new system that could supply reliable, high efficiency cooling across its entire operation.

Solution

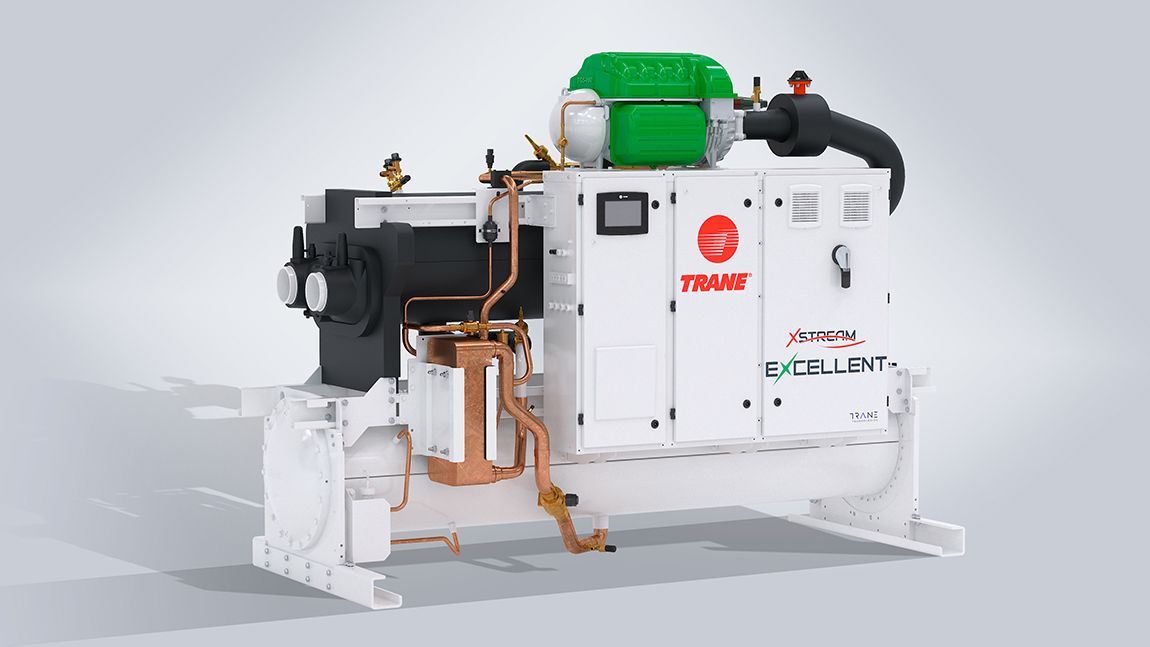

Trane worked closely with the hospital’s contractor to develop and build a state-of-the-art magnetic bearing offering. The GVWF R1234ze Maglev unit supplies cold water to a large water loop that feeds the entire hospital including operating theatres, MRI machines, wards and patient rooms.

The high-speed, oil-free centrifugal compressor use magnetic bearings with integrated variable frequency drive and soft starter module. The unit provides a wide capacity range up to 2.7 MW with industry-leading part load and full load efficiencies, connecting to the larger capacities of the Trane Centrifugal Chiller range up to 14MW, all with near zero HFO.

The GVWF 140 XSE G is rated at 429 kW for a SEER of 9.38 achieving 517 kW as a maximum capacity.

Results

The main hospital drivers are met with the benefits offered by the high efficiency Maglev solution. With only one moving part, the oil-free unit is operationally silent and cost-effective. The magnetic bearing compressor unit brings numerous advantages:

• Increased energy savings

• Improved comfort

• Enhanced sustainability efforts

After other experiences, the hospital has also welcomed access to Trane’s wide service network and capabilities.