Challenge

Internationally renowned chocolate processing company in Germany was looking for a new high efficiency, reliable water-cooled chiller for their warehouse extension. The process cooling system solution should include:

• 500 kW cooling

• Screw Turbo compressor

• HFO refrigerant with near zero GWP for sustainability

• High efficiency for lower energy consumption

• High service quality

Solution

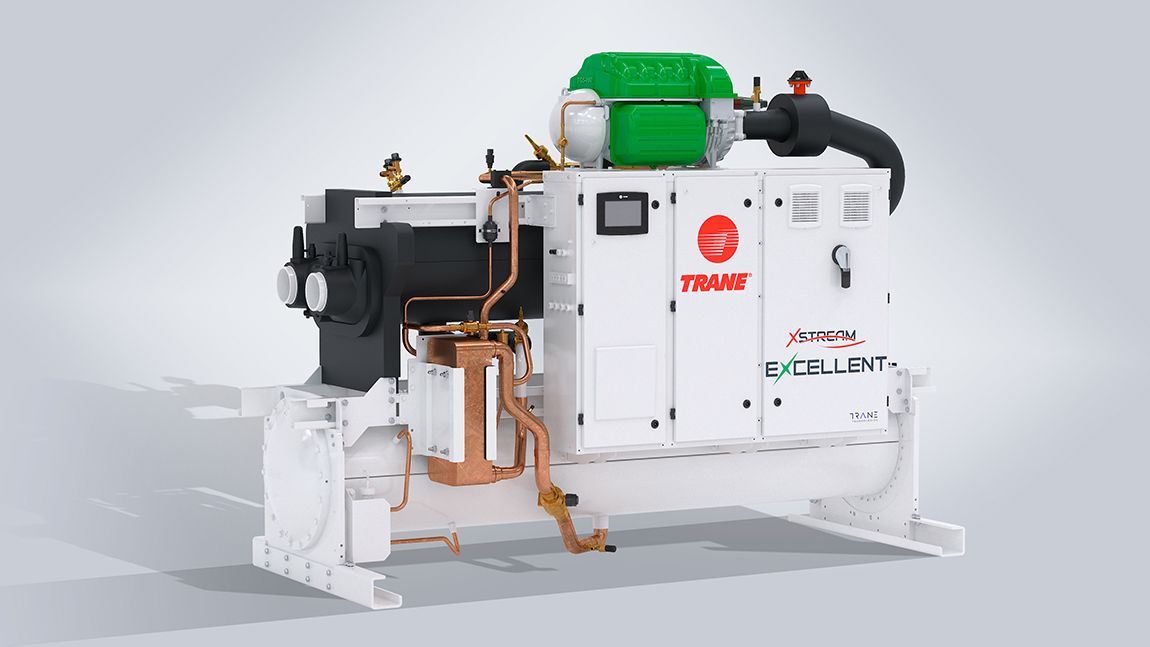

Trane's solution was to provide one GVWF 135G water-cooled chiller using R1234ze refrigerant with near zero GW and a below 1 GWPP. This new system would fulfill all of the cient's requirements for reliability, efficiency and sustainability with:

• 508 kW of cooling

• High Speed Centrifugal Compressor technology

• Net EER at selection point: 5.15

• Unit exceeding ErP thresholds for SEER and SEPR High Temperature

Trane’s additional value to the customer were the following:

• Third-party approved market-leading performance

• Proven product reliability

• Enhanced sustainable solution with low refrigerant content with -30% less refrigerant in system than in traditional shell and tube heat exchangers

• Stable and accurate operation due to Trane adaptive controls

• Easy integration and handling due to ideal unit compactness for indoor installation

• Strong service network capabilities and reliability

Results

This cooling system was set up with startup service in a technical room in the customer's production site. Trane made the difference thanks to its long relationship with the customer but also with the high efficiency and quality of its products supported by very strong and expert services capabilities.