Challenge

A pet food company based in the UK needed to increase capacity with inside storage in a closed area. Their existing inflatable tent-style cold storage setup was leaking and they were struggling to hold their stock at the target temperature of -18°C. Because pet food is also subject to strict compliance regulations and high Environmental, Health and Safety (EHS) standards, a new reliable cold store solution was rapidly needed.

As well as driving improvements regarding their EHS compliance, the customer also wanted to reduce running costs and believed a blast freezer would help them improve their cold store process.

Solution

The specialized Trane Technologies Rental engineers team not only helped devise an innovative solution for the customer but provided technical assistance throughout the project.

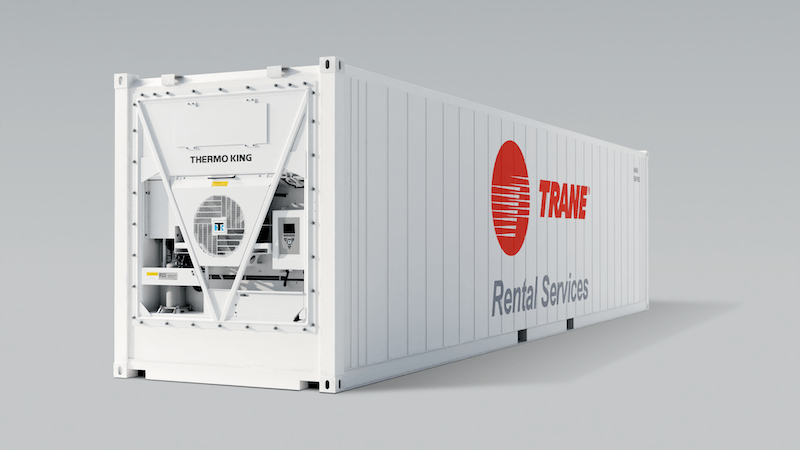

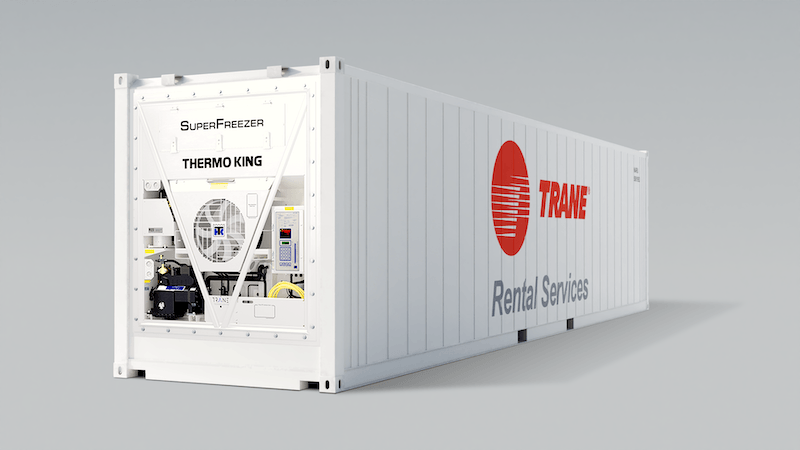

In place of a blast freezer, Trane Rental UK installed a 10' low temperature cold store. Originally designed for seagoing transport refrigeration applications, Trane containerized cold stores can create and maintain ultra-low temperatures of -70°C in -30°C to +50°C ambient air temperatures. In quick pull-down mode, the cold store can provide a very efficient quick chill enabling the customer to take 1,000 kg of processed food from 2°C to -18°C in just over one hour.

Trane also installed four 20' cold stores on site and a full condensate management system.

Results

The customer is very happy with the expanded capacity solution which has increased efficiency, improved EHS compliance and reduced running costs.

Capacity is up by 25% while overall energy consumption has been cut by an outstanding 32%. The use of fully-sealed containers has ensured there is no leaking with condensate collected safely through a number of pumps.

Learn more about "Cold storage"