The average chiller or heat pump contains from 5 to 80 liters of oil, primarily for the lubrication of internal components, particularly the compressor(s). Maintaining high quality oil is critical for reliable unit operation, but how do you ensure your oil quality?

Just like a simple blood test can detect a potential issue with your health, a simple oil analysis can detect a potential problem before it happens. It can predict your equipment’s health.

What are some common issues detected through oil analysis?

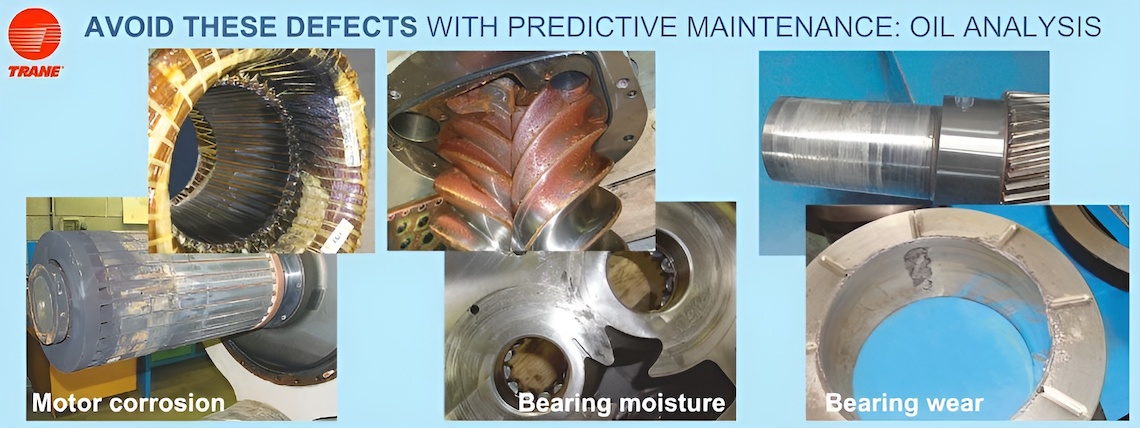

• Issues of chemical nature such as a high level of acidity . Abnormal viscosity due to oil temperature changes caused high acidity. These problems are often caused by internal chemical reactions such as refrigerant alteration or oil hydrolysis. They may result in corrosion on the motor windings and lead to compressor motor burn out.

• Solid particles in the oil cause high wear on components such as bearings reducing compressor life.

• Presence of moisture in oil is contamination that considerably decreases the lifecycle of roller bearings and can lead to corrosion and significant damage. These problems are often caused by oil overheating, bad vacuums, water, refrigerant or air leaks, and additives.

What are the consequences of neglecting regular oil analysis?

When the quality of compressor oil is reduced, there is a higher risk for premature compressor wear, damage or failure.

In the short term, compressor failure means unit downtime repair costs and will immediately negatively affect your building occupants’ comfort or will stop your business’ process.

Long-term consequences include shortened overall lifespan of the HVAC equipment and increased overall cost of ownership.

What information does a Trane oil analysis report contain?

Trane Oil Analysis is based around a range of tests which measure both oil characteristics and compressor wear. A detailed technical report is presented using the Trivector concept for easy understanding. The tests focus on:

Wear:

• Spectrometric analysis to identify wear amount

• Quantity of particles (ppm)

• Nature of particles (additive, wear, pollution)

Chemistry:

• Total Acid Number (TAN)

• Viscosity

Contamination/Moisture presence / Karl Fisher test:

According to the compressor technology and original oil characteristics, the analysis determines 5 alarm levels on each of the three axes. Depending on the results of the oil analysis we may recommend a vibration analysis to give you further peace of mind.

What should facility managers look for in a reliable oil analysis lab?

Selecting a quality service provider is key. Look for an expert that can provide more than a simple oil analysis, for example, who can partner with you to provide other preventive and predictive maintenance procedures such as

- Compressor vibration analysis

- Heat exchanger tube testing

Or for ultimate, comprehensive care, full service agreements.

What do you need to do to get an oil analysis?

To perform a Trane Oil Analysis, your local Trane representative can provide you with an analysis kit with detailed instructions. You simply send your oil sample to the Trane Oil Laboratory. The results will be sent back to you within 5 to 10 days, or even faster for emergency requests.

How often should oil analysis be performed for optimal results?

Regular oil analyses help reduce failure detection time and allows planning for appropriate maintenance. Oil changes can be reduced by half, resulting in lower operating costs and a lower impact on the environment.

Trane recommends one yearly analysis per refrigerant circuit. Regular oil analysis helps reduce the risk of premature damage and can cut the cost and frequency of oil changes.

In summary, high oil quality ultimately ensures

- the longest possible lifecycle for the compressor(s)

- increased HVAC equipment uptime and process uptime

- stable and reliable building occupant comfort

- Improved business productivity: with better visibility, oil changes can be scheduled during the low season or regular shutdowns.

Thanks to our own European laboratory and using the latest technology and equipment, Trane experts apply their vast experience to identify issues through HVAC oil analysis. The Trane oil laboratory has the capabilities and experience to test oil from any type and any brand of equipment including scroll, screw and centrifugal compressors.

Contact your local Trane office to let us check the health of your HVAC equipment.

Schedule your Trane tube testing today

Contact Us

Connect with your local Trane expert

We will help you find the needed solution