Analýza vibrácií

Prediktívny servis na zvýšenie spoľahlivosti kompresora

- Analýza zmien vibračnej signatúry zariadenia

- Zisťovanie zdroja a úrovne vibrácií

- Identifikácia nevyváženosti hriadeľa

- Dôkladná analýza odborníkmi na kompresory Trane

Zvýšenie spoľahlivosti systému a predchádzanie rizikám vďaka včasnému odhaleniu poruchy

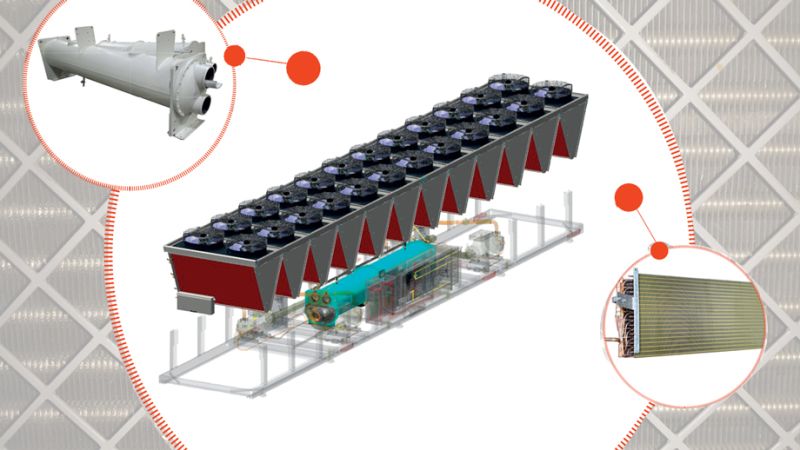

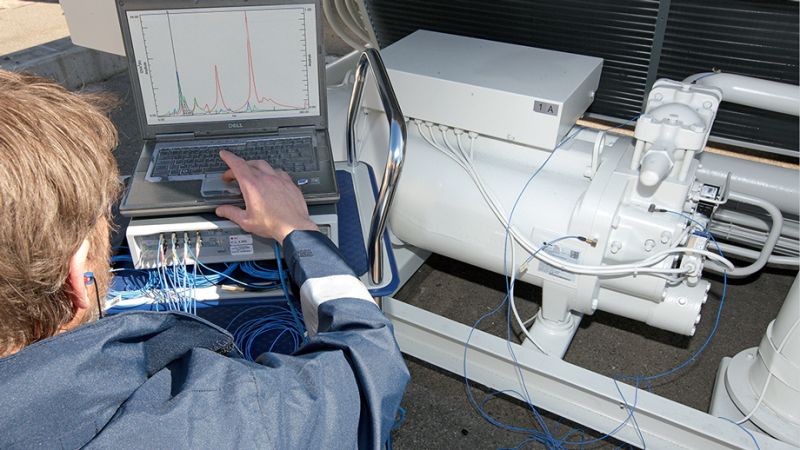

Vibračná signatúra pracujúceho zariadenia poskytuje podrobnejšie informácie o stave vnútorných komponentov než iné nedeštruktívne metódy, ako sú infračervené alebo elektrické techniky. Vibračná analýza spoločnosti Trane je použiteľná pre všetky typy technológií rotačných kompresorov. Je súčasťou ponuky Trane Building Advantage, ktorá je určená na zabezpečenie vášho systému do budúcnosti.

Každý kus zariadenia HVAC s rotujúcimi komponentmi má svoj vlastný vibračný podpis. Akákoľvek zmena tohto podpisu sa dá použiť ako presný prostriedok na identifikáciu vznikajúcich problémov, ako je opotrebovanie ložísk, nevyváženosť hriadeľa a zhoršujúca sa tolerancia rotora skrutkového kompresora. Monitorovací a diagnostický systém spoľahlivo odhalí všetky typy porúch a úrovne závažnosti. Analýza vibrácií dokáže identifikovať problémy dlho predtým, ako ovplyvnia spoľahlivosť kompresora.

Hĺbková analýza odborníkmi na kompresory Trane

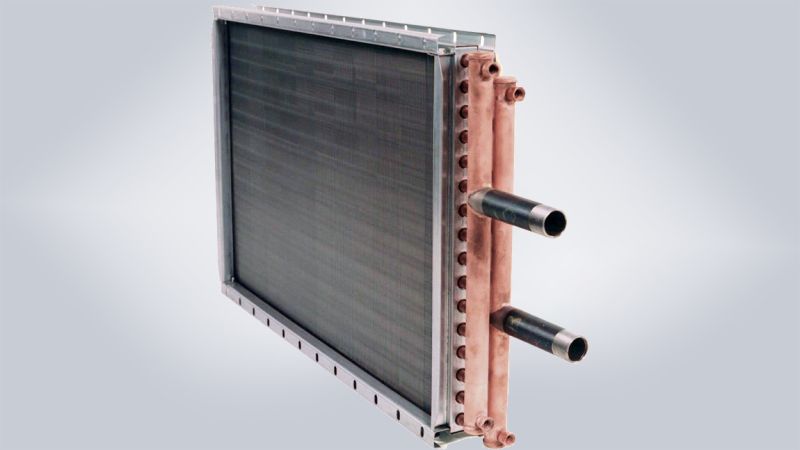

Metódy merania a analýzy vibrácií, ktoré používa spoločnosť Trane, predstavujú kompletnú ponuku starostlivosti o kompresory, ktorá dokáže identifikovať širokú škálu vznikajúcich porúch, ako je nesprávne nastavenie hriadeľa, chyby ložísk, nevyváženosť alebo elektrické problémy motora.

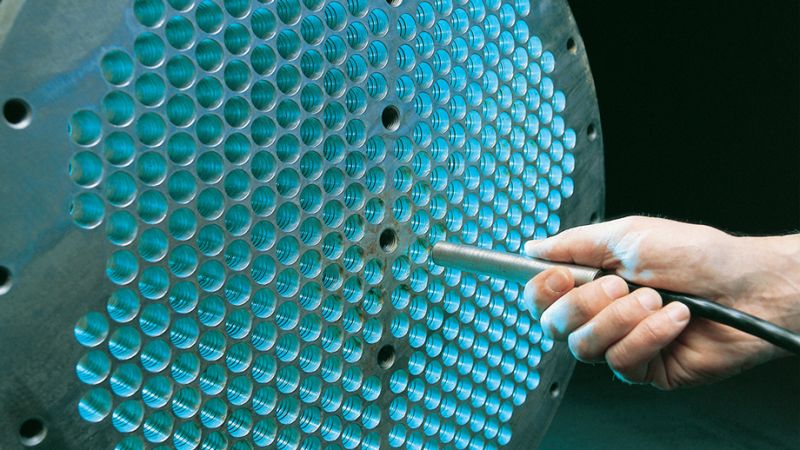

Jednoduché meranie len celkovej úrovne vibrácií nie je dostatočné, preto spoločnosť Trane vykonáva aj úzkopásmovú frekvenčnú analýzu na určenie konkrétneho typu rozvíjajúceho sa problému. Informácie o kinematike kompresora potrebné na vykonanie tejto úrovne podrobnej analýzy jednotiek Trane pozná len spoločnosť Trane.

Jasná a podrobná správa poskytuje stav častí kompresora s odporúčaniami na plánovanie údržby.

Analýza vibrácií spoločnosti Trane je súčasťou programu Trane Building Advantage. V spojení s analýzou oleja a Compressor R'Newal poskytuje jasnú, úplnú a hĺbkovú cestu, ktorá vám umožní zvýšiť spoľahlivosť vášho systému a znížiť prevádzkové náklady.

Kedy je potrebná analýza vibrácií?

Keď analýza oleja odhalí prítomnosť opotrebenia, ktoré naznačuje začiatok možnej poruchy ložiska alebo motora. Analýza oleja spoločnosti Trane určuje typ kovových častíc v oleji. V kombinácii s analýzou vibrácií sa jasne identifikujú zlyhávajúce komponenty.

Analýza vibrácií by sa mala vykonávať pravidelne, aby sa vytvoril trend vibrácií zariadenia a predišlo sa neplánovaným odstávkam a

nákladom.

Zdroje

| Elektronická brožúra produktu PDF dokument | Stiahnite si |

|---|

Kontaktujte nás

Spojte sa s miestnym odborníkom spoločnosti Trane

Pomôžeme vám nájsť potrebné riešenie