In today's competitive environment, maintaining high equipment reliability while minimizing operating costs is crucial. One of the most effective predictive tools for achieving this is vibration analysis. This non-destructive method has become the preferred choice for monitoring the condition of compressors and other HVAC equipment, providing detailed insights that other methods like infrared or electrical analysis cannot match.

Predictive Service for Increased Reliability

The need for greater equipment reliability at lower operating costs calls for innovative, proven, and practical solutions that can be quickly implemented to produce fast cost savings. Vibration analysis stands out as a key player in this arena. It offers a detailed vibration signature of running equipment, which can reveal the condition of internal components more accurately than other non-destructive methods.

Benefits of Vibration Analysis

Every piece of HVAC equipment with rotating components has its own unique vibration signature. Any change in this signature can serve as an accurate indicator of developing problems such as bearing wear, shaft imbalance, and degrading screw compressor rotor tolerance.

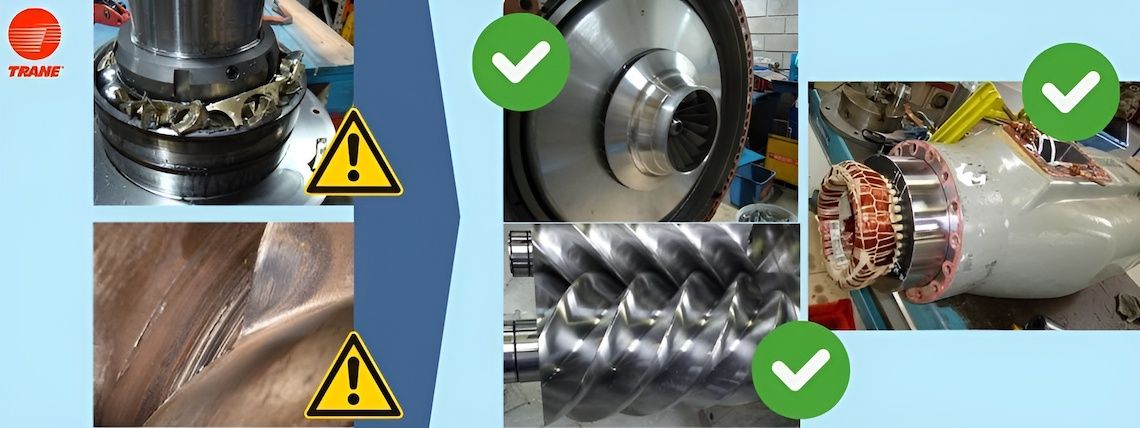

(see compressor damage due to lack of maintenance, #1 in image below)

Trane's monitoring and diagnostics system reliably detects potential defects at their initial stages, identifying the exact defect type and its severity. This allows for problems to be identified long before they become noticeable in the environment.

Risk Removal

Trane's vibration analysis enables a shift from a 'run to failure' mode to a more predictive maintenance approach. This transition helps avoid the high costs associated with emergency repairs and minimizes expenses related to equipment downtime. By increasing operating reliability and improving the Mean Time Between Failure (MTBF), vibration analysis can significantly lower your repair bills.

Part of A Complete Offer

When combined with oil analysis and Compressor R’Newal, it provides a comprehensive path to increased reliability and lower operating costs.

(see compressor overhaul, #2 and #3 in image below)

When is Vibration Analysis Required?

1. Oil Analysis Indications: When an oil analysis reveals the presence of wear, indicating the start of possible bearing or motor failure. Trane's oil analysis determines the type of metallic particles in the oil. When combined with vibration analysis, failing components are clearly identified.

2. Regular Monitoring: Vibration analysis should be performed regularly to build a vibration trend of the equipment, helping to avoid unplanned downtime and costs.

Vibration Analysis by Trane

Trane's analysis techniques can identify a wide range of developing faults such as shaft misalignment, bearing defects, imbalance, or motor electrical problems. Measuring the compressor's overall vibration level alone is not sufficient. A narrow band frequency analysis is needed to indicate the specific type of developing problem. To conduct this detailed analysis, it is essential to know the compressor kinematics, including the natural frequencies and speed of all rotating parts. Only Trane has this information for its compressors.

Vibration Analysis Results

Much like a doctor examining a patient, Trane's experts meticulously monitor every essential part of your equipment. Using highly sensitive sensors installed in carefully selected places, they detect and record even the smallest deviations or abnormal behaviors. The vibration spectrum of your equipment, akin to an electrocardiogram, illustrates its internal condition. These graphs are explained to you in a simple and clear manner. Additionally, Trane provides maintenance scheduling recommendations based on the vibration analysis report. If an imminent compressor fault is detected, they will advise you on how to plan for a scheduled compressor renewal.

In conclusion, vibration analysis is an indispensable tool for maintaining the highest level of reliability for your compressors. By identifying potential issues early, it helps you avoid costly repairs and downtime, ensuring your equipment operates smoothly and efficiently. With Trane's comprehensive approach, you can achieve increased reliability and lower operating costs, making it a smart investment for any business.

Contact your local expert today

Contact Us

Connect with your local Trane expert

We will help you find the needed solution