Improve Operations

A comprehensive portfolio of solutions to meet your sustainability goals

Reliability is always our first concern

Full OEM support

Technology is continuously evolving and Trane Engineering is ahead of the curve in bringing innovation into product development. Our sustainable solutions deliver enhancements to the Trane installed base to make your chillers and heat pumps even "better than before". That's Trane Building Advantage - TBA.

Energy efficiency solutions

Trane Building Advantage offers a complete and growing portfolio of solutions to enhance your system efficiency at component or plant level with lower energy consumption, access to renewable sources (to displace fossil fuels usage) and reduced carbon footprint.

Your equipment will be “Better than before” demonstrating a tangible impact on energy bills and CO2 emissions. Highly recommended for energy intensive applications, Trane Building Advantage provides a quicker return on investment.

Refrigerant management

Refrigerants have a direct impact on global warming depending on their potential (GWP). EU F-GAS regulation is putting pressure on the use of high GWP refrigerants with bans, reduction of availability and fines for non-compliance.

We can help you maximize compliance and efficiency by reducing GWP. Trane offers factory-engineered solutions with no compromise on equipment reliability. We will help you reduce your carbon footprint and avoid scarcity of supply.

Future proof your system

TBA means you can check and upgrade your system to protect your investment, maximize uptime and extend its lifetime. You can also leverage new functionalities and insights with the latest generation of controls and connectivity options.

Metering & Controls

Performance assessement is key to making your facility more energy efficient. At Trane, we start with the data. We use intelligent tools to monitor, track, predict and optimize your operation. We offer energy management solutions tailored to your business’s needs to deliver improved building performance, sustainability and operating costs.

Improve Operations

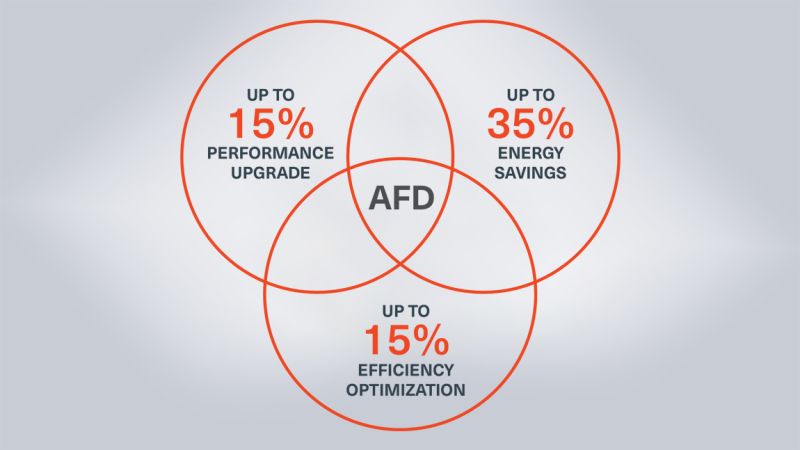

Adaptive Frequency Drive

- Precise capacity control

- Save energy and cut your operating costs

- Up to 50% part load efficiency improvement

- Reduce start up current by 85%

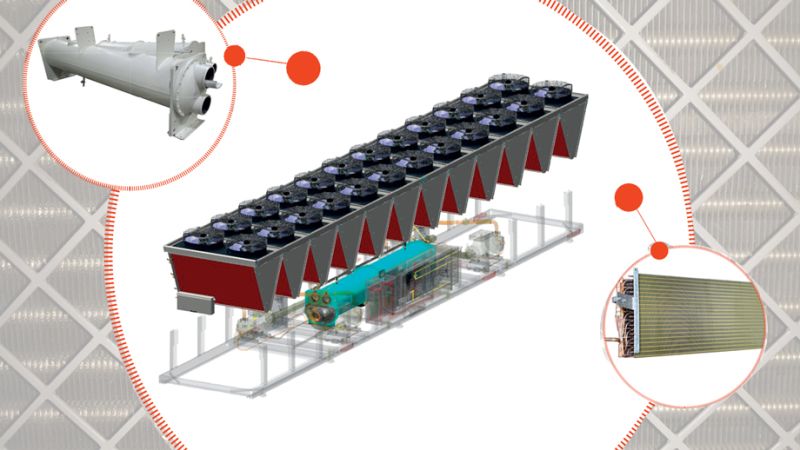

Exchanger cleaning

- Avoid dust and sand on coil

- Avoid exchanger fouling

- Reduce oil and discharge temperature

- Reduce chiller power consumption and increase chiller capacity

- Avoid high pressure cut out at very high ambient temperatures

Automatic Tube Cleaning

- Permanent cleaning

- Zero environmental impact

- No chiller downtime

- Suitable for all chillers

- Low system operating cost and maintenance savings

Adiabatic Cooling

- Energy savings

- Enhance compressor lifetime

- Maintain cooling capacity above design ambient temperature

- Flexibility: can be adapted to any coil

- Simple installation

Heat Recovery

- Recover free energy

- Rapid payback time

- Hot water up to 70°C

- No increase in footprint

- Easy installation

AdaptiFan

- Up to 6% efficiency improvement

- Increase fan reliability

- Better unit operation

- Fast and non invasive installation

Refrigerant Leak Testing

- Leak detection routines

- Identify leak location

- Detect any refrigerant type (CFC, HCFC, HFC)

- Early corrective actions can prevent leakage and avoid unplanned downtime

- Ensure refrigerant stays within the chiller

Refrigerant Monitoring

- Permanent leak detector

- Optional carbon monoxide and oxygen sensors

- Multiple refrigerant sensing capability

- BMS interface capability

- Alarms

Refrigerant Retrofit

- For chillers from 200 to 1400 kW

- Replacement of HFC refrigerants (such as R134a or R404A) with low GWP refrigerant R513A

- Only 3% cooling capacity reduction

- 50% reduction of chiller carbon footprint

- Environmental protection

Chiller Control Upgrade

- Comprehensive retrofit package to the most advanced chiller control technology

- At-a-glance status with key operating parameters

- Digital services ready

- Customizable routines

- Ergonomic design

Oil Analysis

- Detect changes in oil characteristics

- Available for all compressor brands and types

- State-of-the-art Trane oil laboratory

- Detailed technical report with corrective recommendations

- Risk assessment

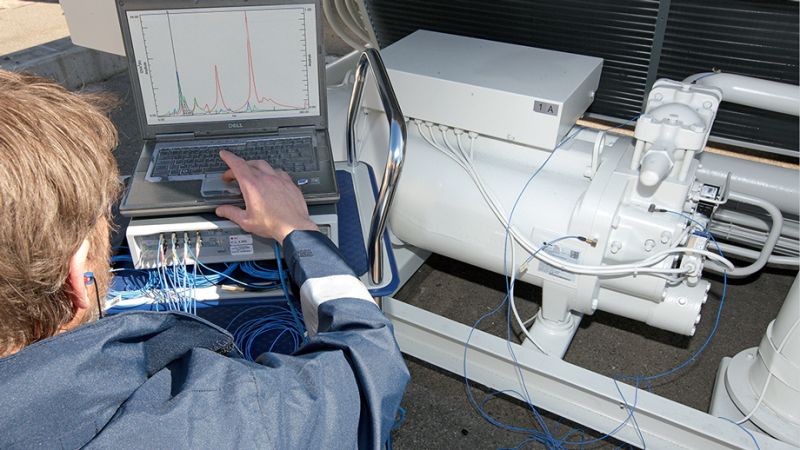

Vibration Analysis

- Analyze changes in the equipment vibration signature

- Detect source and level of vibration

- Identify shaft unbalancing

- Thorough analysis by Trane compressor experts

Compressor R'newal

- Restore compressor reliability and performance

- Replacement of wear-sensitive parts

- Run tested prior to installation

- Retrofit at Trane factory

- Operation under qualified Trane technicians

Exchanger cleaning

- Avoid dust and sand on coil

- Avoid exchanger fouling

- Reduce oil and discharge temperature

- Reduce chiller power consumption and increase chiller capacity

- Avoid high pressure cut out at very high ambient temperatures

Automatic Tube Cleaning

- Permanent cleaning

- Zero environmental impact

- No chiller downtime

- Suitable for all chillers

- Low system operating cost and maintenance savings

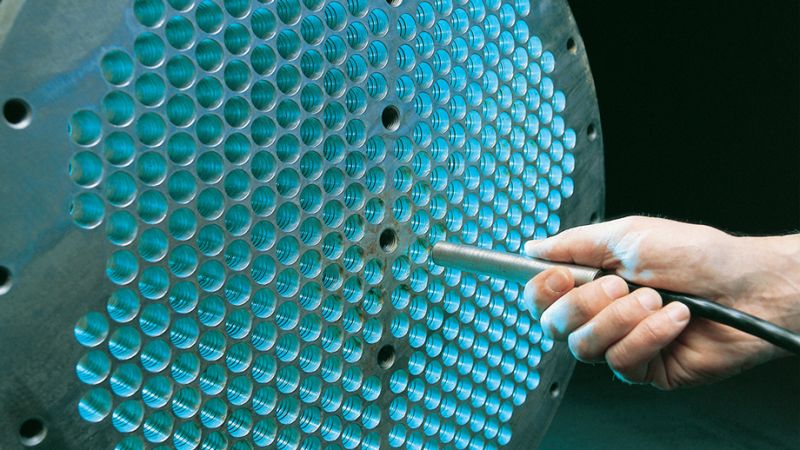

Tube Testing

- Identify conditions of any tubes exchanger

- Eddy Current tube testing

- Report nature of defects

- Identify cause of failure

- Comprehensive report with recommendations for corrective actions

Exchanger Enhancement

- Chemical protection of critical chiller components (coil on air-cooled chiller, condenser on water-cooled chiller)

- Protection from corrosion

Water Analysis

- Detect changes in water characteristics

- Control antifreeze capability

- Prevent damage risks in your heating or cooling system

Additional services to help you succeed

Contact Us

Connect with your local Trane expert

We will help you find the needed solution